StreetIQ, an AI-powered infrastructure intelligence company, publicly launched today following two years of product development and early customer validation. The company’s AI technology empowers cities and counties to replace manual, subjective infrastructure assessments with a defensible, automated system of intelligence for planning, compliance, and budgetary decision-making.

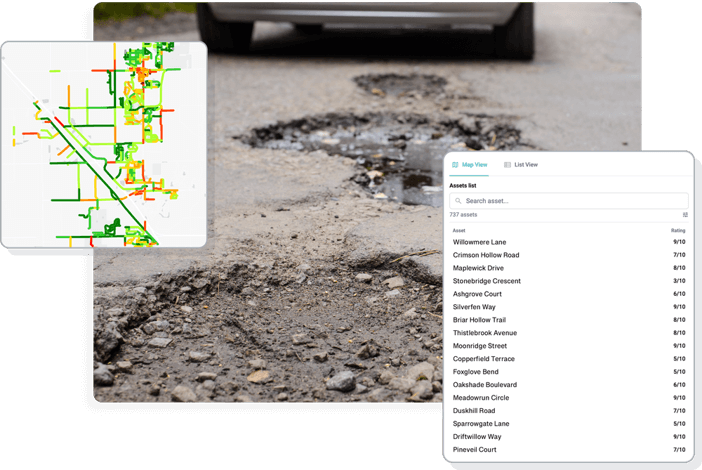

StreetIQ applies computer vision and machine learning to score street-level imagery, enabling public agencies to objectively assess roadway conditions, standardize reporting, and clearly communicate progress to stakeholders. The platform is designed to support the full lifecycle of infrastructure decision-making, from data collection and analysis through to planning, treatment recommendations, budget optimization, and council-ready reporting.

“For too long, infrastructure teams have been stuck in a cycle of scrambling — collecting data by hand, stitching together spreadsheets, and trying to justify decisions under intense time and budgetary pressure,” said Joe Becker, Chief Executive Officer of StreetIQ. “StreetIQ exists to simplify that entire journey. We help agencies move from reactive maintenance to proactive planning, with data they can stand behind and decisions they can defend.”

Becker was recently appointed to lead StreetIQ, and brings hands-on experience of working with public agencies, infrastructure operators and scaling enterprise software companies. Under Becker’s leadership, StreetIQ is prioritizing automation, standardization, and ease of use, to help customers reclaim time, plan further ahead, and make smarter use of constrained budgets.

The technology behind StreetIQ has been built over the past 18-months by Chief Technology Officer and Co-Founder Brian Howenstein, who has led development of the company’s core platform while operating in stealth.

“Our focus from day one has been accuracy, repeatability, and defensibility,” said Howenstein. “Infrastructure decisions carry real financial and political consequences, so the data has to be trustworthy. By combining modern camera technology with AI-driven analysis, we’ve built a system that produces consistent results across jurisdictions and over time, something legacy, manual approaches simply can’t do.”

StreetIQ’s platform replaces subjective windshield surveys and fragmented reporting workflows with a standardized, auditable process. Agencies can track asset conditions over time, test funding and maintenance scenarios, and align spending decisions with long-term performance goals, all while meeting state and federal compliance requirements.

The company is backed by HG Ventures, the corporate venture capital arm of The Heritage Group. HG Ventures invests in technologies that modernize critical infrastructure and improve operational decision-making. This partnership reflects the strategic value The Heritage Group’s operating companies and deep technical expertise help high-growth businesses solve real-world construction and operations challenges.

“StreetIQ is addressing a persistent challenge we see across infrastructure systems: important decisions being made with incomplete, inconsistent, or hard-to-defend data,” said Mitch Black, Venture Partner, HG Ventures. “The combination of a technically rigorous platform and a leadership team that deeply understands public-sector realities positions StreetIQ to deliver real, measurable impact for infrastructure owners.”

With its public launch, StreetIQ’s focus turns to growing its customer base across cities, counties and regional engineering firms. StreetIQ is empowering budget compliant defensible decisions that turn real world complexity into clear, actionable intelligence while improving safety and access for the traveling public.